Challenges of Decarbonization in Extreme Climates

December 18, 2023 | By: Casey Ross, P.E.

A Plan for Net Zero-Ho-Ho

The pace of decarbonization and reduction of carbon from buildings is increasing around the world. But what challenges will designers face when working in more extreme climates? Very cold climates have historically relied on fossil fuels as a necessity for building heating. With some smart planning, that need not be the case anymore. Let’s build net zero for Santa.

THE SITE

Santa’s house and workshop are in the appropriately named Santa Claus Village. Christmas is every day in this charming town, located in northern Finland at the Arctic circle. The location is classified as ASHRAE Climate Zone 7A with peak heating in February at a 99.6% design condition of -8.8F. Brrr! Summertime gets to a more pleasant 0.4% peak of 79.2F in July.

THE BUILDING

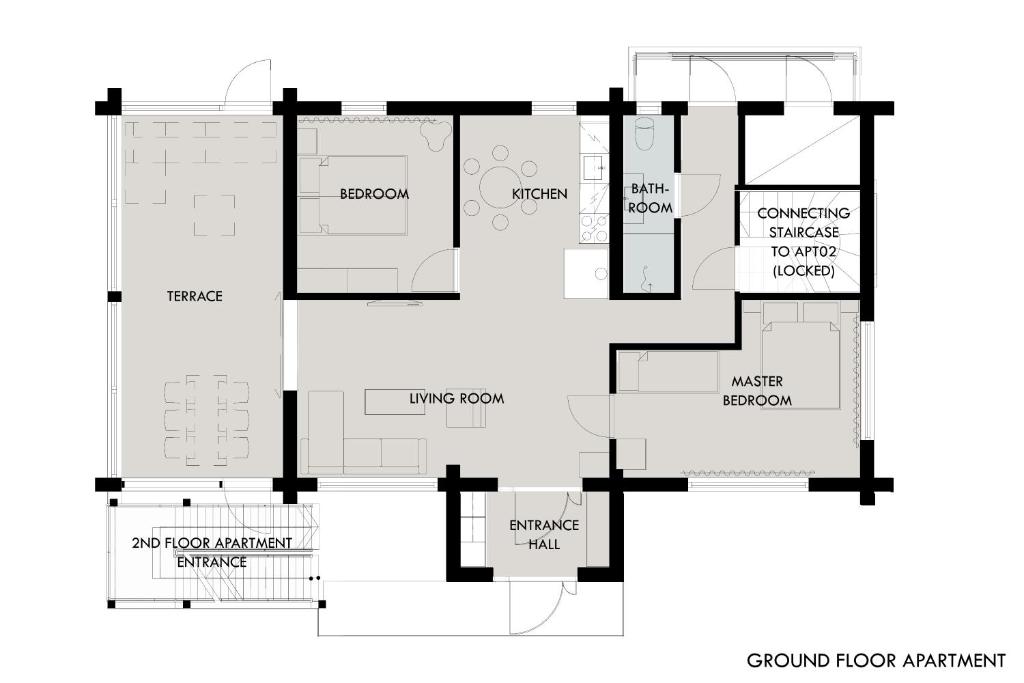

Santa’s house is a 2,500 square foot, two-story dwelling inspired by this listing on Booking.com called Santa’s Luxury Boutique Villa Apartment.

The workshop is a plainer 10,000 square foot single-story warehouse structure.

The construction of the building envelope will need to be well-insulated. ASHRAE minimums for this climate zone are R-22 walls, R-38 roof, and glazing performance of U-0.30 / SHGC-0.39. To be net zero, the project will elect to increase those values to R-30 walls and R-45 roof, adding about 2″ of batt insulation thickness all around. Glazing specifies a high-performance triple-paned glass with thermal properties of U-0.25 / SHGC-0.39.

Santa is buying all Energy Star appliances with top-of-the-line LED lights. The project energy budget thus will call for 0.35 W/SF appliances and miscellaneous loads and 0.40 W/SF lighting power for the house, and 0.25 W/SF miscellaneous loads and 0.30 W/SF lighting power for the workshop. Attic spaces above both Santa’s house and his workshop have no lights or miscellaneous loads. See Santa’s Site Consumption Summary.

Santa is buying all Energy Star appliances with top-of-the-line LED lights. The project energy budget thus will call for 0.35 W/SF appliances and miscellaneous loads and 0.40 W/SF lighting power for the house, and 0.25 W/SF miscellaneous loads and 0.30 W/SF lighting power for the workshop. Attic spaces above both Santa’s house and his workshop have no lights or miscellaneous loads. See Santa’s Site Consumption Summary.

THE SYSTEMS

The project needs to start with a high-efficiency, all-electric HVAC system. Geothermal heat pumps might prove to be cost prohibitive due to the extreme freezing conditions in this climate. The design, thus, is electing to use an air-source heat pump for main heating and cooling. The heat pump will be a low GHG, CO2-based system designed to operate as low as -10F ambient outdoor air temperatures. A wind wall will be built near the heat pump equipment to eliminate wind chill factor on HVAC performance. Electric resistance heating will be used to serve the last 5% of the peak heating load to keep equipment at a reasonable size and cost. Ventilation air will be treated with total energy heat recovery wheel. All cooking will be via induction stoves.

Domestic hot water will be generated by a similar air-source heat pump, utilizing heat recovery coils from the shower drains for additional heat recovery. All told, this comes to a peak heating load of 85.5 kBTUH for HVAC and another 4.3 kBTUH for domestic hot water. This is great news, as a single 90,000 BTUH air-source heat pump can serve the entire house and workshop, relying on a small heat exchanger to warm up the domestic water storage tank.

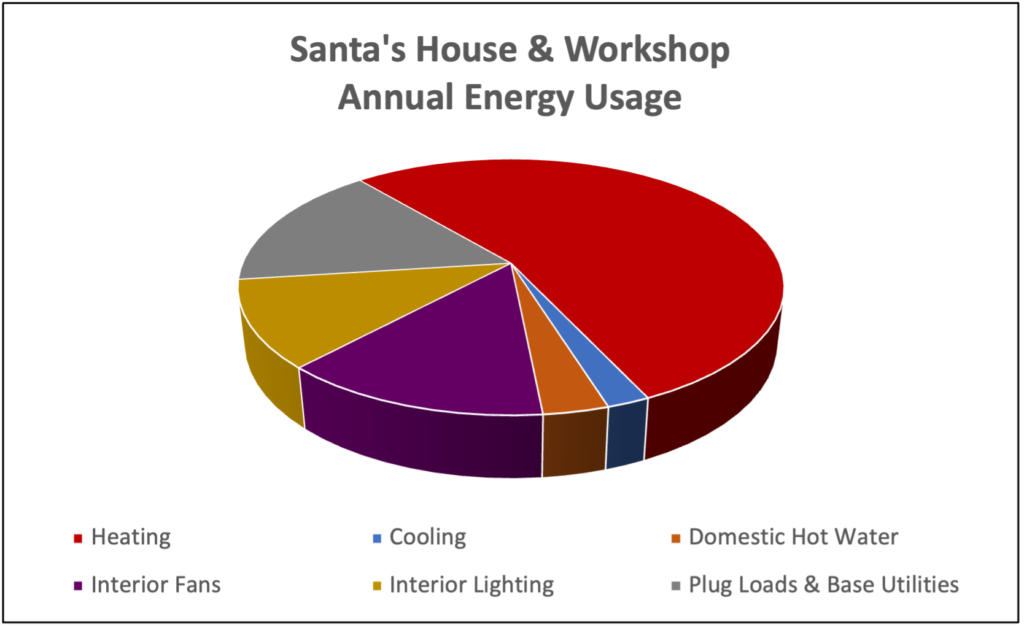

A good target energy use intensity (EUI) of 20 kBTU/sf/year is a start, and our energy model (above) shows the project at a resultant EUI of 10.8, a great sign! This leaves an energy deficit of 76,195 kWh, which will need to be offset by clean renewable energy sources.

RENEWABLES

The project goal is to be net zero for the year. The overall strategy will be to reduce site energy as low as possible and then generate excess energy in the summer through solar photovoltaics (PV) to offset the deficits of the winter. On-site wind generation coupled with cost-effective iron-based battery energy storage will also be included to provide a more continuous source of building site energy. And of course, no fossil fuels will be used on site.

SOLAR

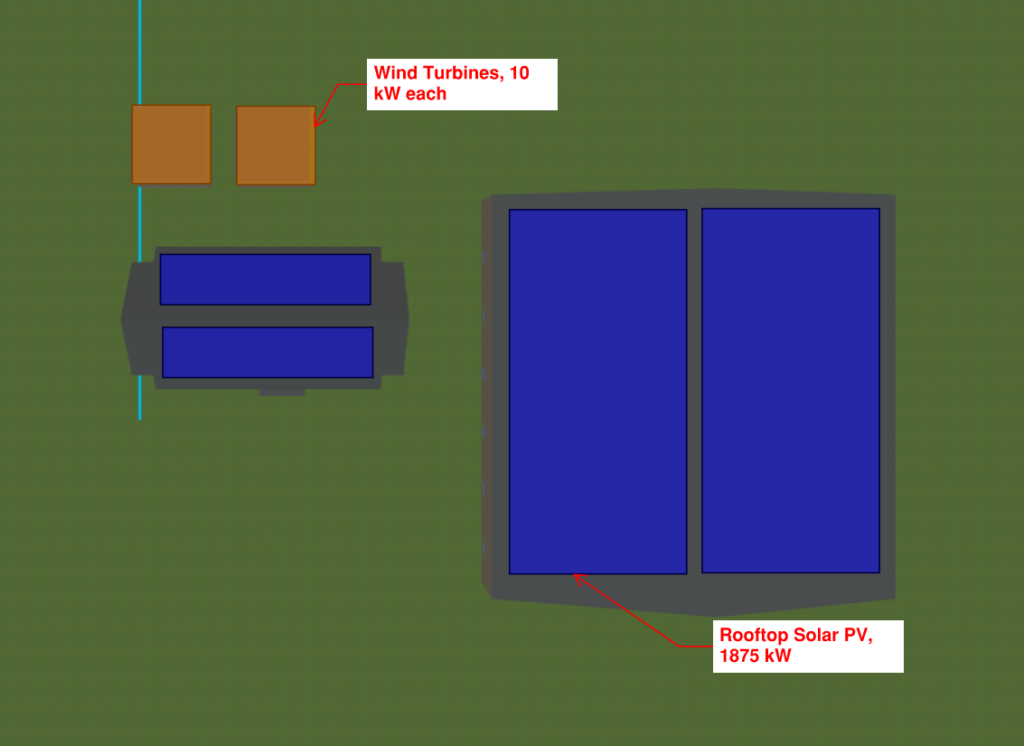

In the summer, the site sees almost continuous sunlight. The project will maximize its solar potential by placing panels across the roof with an estimated 11,250 square feet of panels. Using the National Renewable Energy Laboratory’s calculator, a Premium module, 2-Axis tracking panel will generate approximately 924 kWh per year. A panel is about 6’x3′ and 400 watts, meaning that each square foot of rooftop solar nets the project about 20 kWh per year. Thus, the project sees about 25,000 kWh per year generated by rooftop solar.

WIND

Wind power is an important renewable resource for this project as well. A typical residential-scale 10 kW wind turbine has a footprint of roughly 16 feet by 16 feet. At the moderately windy location of northern Finland, a capacity factor of 0.20 is expected, yielding a full-year power generation rate of 21,900 kWh per turbine. To make up for the yearly power deficit remaining of 51,195 kWh, the elves need to install just two new wind turbines as well.

CONCLUSION

Net zero is not just a possibility, Santas Luxury Villa Project Summary. Santa and his elves have helped create this thought experiment to showcase where the technology is today. Lorax can help you understand both the technical requirements of net zero projects and how to leverage Federal and local incentives to finance your own dream of a white Christmas.